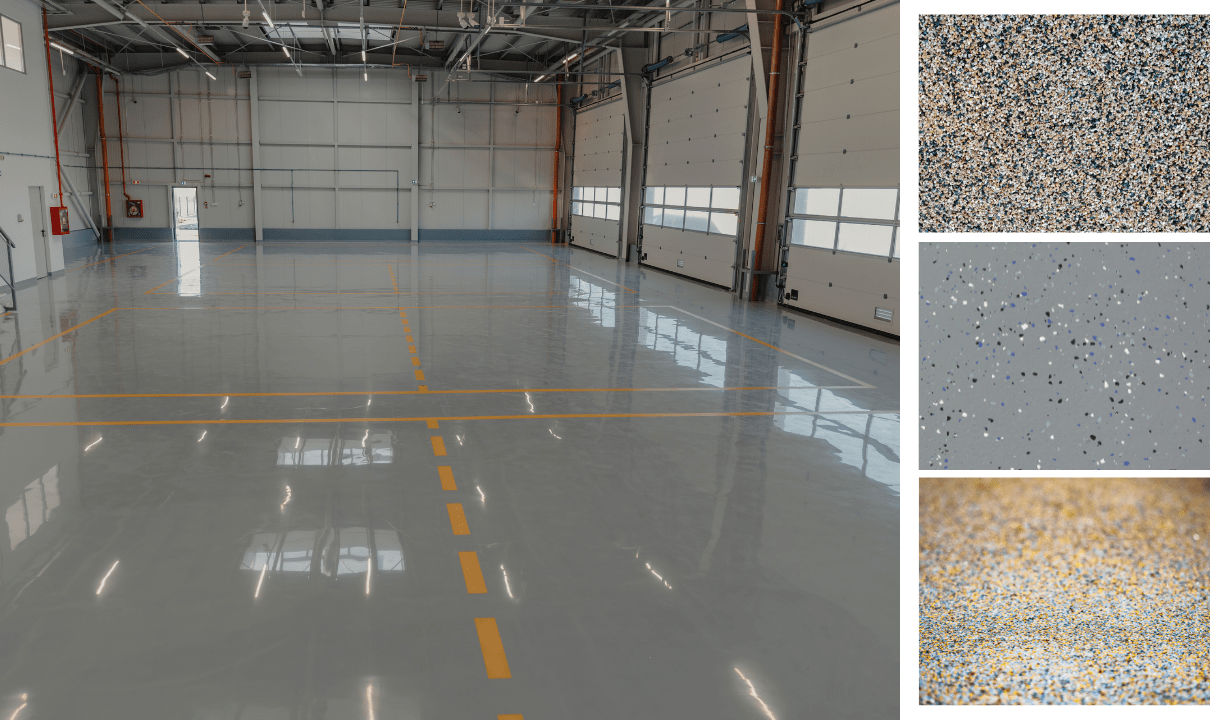

NeverStrip Epoxy 100 Color is a 100% solids, pigmented epoxy floor coating designed to provide high gloss, chemical resistant protection in multiple color choices. NeverStrip Epoxy 100 Color should be used wherever a high build, protective floor coating is required.

What is NeverStrip Epoxy 100 Color?

NeverStrip Epoxy 100 Color is a 100% solids, high build pigmented epoxy floor coating designed to provide high gloss, chemical resistant protection in multiple color choices.

NeverStrip Epoxy 100 Color is used wherever a high build, protective floor coating is required.

NeverStrip Epoxy 100 Clear is a two-component, 100% solids, epoxy floor coating designed to provide high gloss, chemical resistant protection. NeverStrip Epoxy 100 Clear should Be used wherever a high build protective floor coating is required. NeverStrip Epoxy 100 Clear can be used as a body coat for NeverStrip single and double broadcasted systems with

NeverStrip Extreme Performance or NeverStrip High Solids Urethane as a topcoat

Key Considerations

1 . Substrate temperature must be

a minimum of 50ºF.

2 . Substrate must be free of dirt, waxes,

curing agents and any other foreign

materials.

3 . Not recommended for immersion in

oxidizing agents or mineral acids

Surface Preparation

Surface Preparation is the most critical portion of any successfulresinous flooring system application. All substrates must be properly prepared as outlined in NeverStrip Technical Document – Concrete Preparation. NeverStrip Epoxy 100 Clear ideally bonds to concrete with

a rough sandpaper finish. Concrete must be structurally sound. All concrete can be acid etched or mechanically prepared by vacuum shot blasting, sand blasting, scarifying or grinding.The concrete must be examined for moisture vapor transmission. The maximum allowable rate is a RH (Relative Humidity) up to 80%. If the moisture levels exceed this rate, then a proper moisture mitigation system must be installed. New concrete must be well cured and dry prior to coating. Allow concrete to cure 28 days unless green concrete primer is used, such as NeverStrip’s Off-Gassing Primer.

Mixing

Pour Part A into a larger container; drill for 30 seconds. Pour Part B into the same container; drill for 3 minutes. If product is not pre-pig

Application

NeverStrip Epoxy 100 Clear is normally poured onto the floor and spread with a trowel or notch squeegee and back-rolled with a 3/8″nap woven roller. Use a flexible smooth squeegee with applying Body Coat for a broadcast system. Care should be taken to minimize the entrapment of air caused by over-rolling.The use of an appropriate off-gassing primer is recommended NeverStrip’s Broadcaster Primer or NeverStrip Epoxy Primer or

NeverStrip’s Off-Gassing Primer are recommended.

Coverage

NeverStrip Epoxy 100 will yield approximately 10 mils when spread at 160 sq ft per gallon. MIL thickness can vary greatly. Mil thickness of 15-20 mils is common producing coverage of 80 to 120 sq feet per gallon.

Cure/Dry Time

1 . In-Use Time: 20-30 minutes @ 75ºF

2 . Re-Coat 12 -16 hours @75ºF

3 . Light Service 24 hours @ 75ºF

4 . Full Cure 5 days

NeverStrip Epoxy 100 Color-Corporate Clean LLC

NeverStrip Floor Coatings manufactures floor coatings with a difference. These coatings are used in all sorts of different environments — from commercial and industrial spaces to residential homes. They are designed to lower long-term floor care costs, enhance your floors’ appearance, and also often to improve floor traction. contact us today to get a free quote on new floor coatings!