Neverstrip Epoxy Primer:

NeverStrip Off-Gassing Primer is a water emulsion epoxy primer designed to have maximum penetration into concrete surfaces to provide high bond strength and adhesion. The product is specially formulated to reduce concrete off gassing.

Surface Preparation and Mixing

NeverStrip Epoxy Primer is a two-part material. Part A and Part B are supplied in the correct mixing ratios. Always mix a complete unit in the proportions supplied. Add one (1) part of NeverStrip Epoxy Primer Part A to four (4) parts NeverStrip Epoxy Primer Part B. Thoroughly

mix with a low speed drill and Jiffy blade for 3-4 minutes until uniform. Do not entrap excessive air. Scrape all sides and bottom of container to ensure thorough mixing.

Application

Apply to the properly prepared substrate with a notch squeegee at coverage rate of 100 -160 sq ft per gallon and backroll with 3/8” nap roller to achieve uniform coverage. Allow to cure hard enough for foot traffic, about 3-4 hours at 75ºF.Broadcast the desired 30 mesh sand or quartz blend at 1/2 pound per square foot or to rejection. Typically apply next “Body” coat in 4 hours

Characteristics

Low VOC, water based

White Color

Vapor and water barrier

Accepts and holds sand and quartz

broadcast

High moisture tolerance

Does not support mold

Minimal downtime

Key Considerations

Substrate temperature must be50ºF minimum.

Substrate must be free of dirt, waxes,

curing agents, and any other foreign

materials.

Must be installed a minimum of 1/8″

for use with moisture sensitive floors.

Shot blast or rough grind concrete slabs

to create a coarse texture surface profile.

(minimum CSP-3).

NeverStrip Epoxy Primer

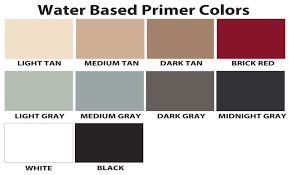

NeverStrip Epoxy Primer can be tinted in any of the “W” Colors on this Color Chart. This product is fast drying, odorless, bonds well to many flooring surfaces and hides the floor extraordinarily well. Typically, this product is the first coat of a NeverStrip Color System to transform a floor.

Color and Epoxy Primer Color Chart

Available in 55 vibrant colors with the highest quality color pigments – that can be further enhanced with colored flakes for endless custom floor transformations You and your designers imagination have virtually no limits. Imagine how a 2 or more color design could transform an old tired floor.Color applications typically, include a NeverStrip clear topcoat in 1 of 3 sheens (Gloss, Satin, or Matte). This color system is used to rejuvenate and re-color worn synthetic sports floors, Vinyl Asbestos Tile, VCT, and Concrete for a cost effective transformation, with

ease of maintenance, yet a high level of sustainability. Color and Epoxy Primer Color Chart

White Clear White Clear

D372 W450

D391

D407

W472

W476

D425

D442

W467

W468

W416

W469

W466

W477

W417

D418

W218

W216

W212

W211

W209

W210

C217

C202

C207

C203

C204

C201 W213

W220 C219

W222 C221

W215 C206

W214 C205

W208 C200

W458

W460

W428

W449

W421

W430

W459

W465

C410 C337

C313

C317

C397 C336

C375

Color applications typically, include a NeverStrip clear topcoat in 1 of 3 sheens (Gloss, Satin, or Matte). This color system is used to rejuvenate and re-color worn synthetic sports floors, Vinyl Asbestos Tile, VCT, and Concrete for a cost effective transformation, with ease of maintenance, yet a high level of sustainability.

Cleaning and Maintenance

After completing the application of NeverStrip Epoxy Primer and the topcoats, the installer should provide the owner with cleaning and maintenance instructions relevant to the specific

primer or topcoat. If floors become slippery due to animal fats, oil, grease, or soap film, clean and rinse thoroughly.

Neverstrip Micron Floor Coating-Corporate Clean LLC:

NeverStrip Floor Coatings manufactures floor coatings with a difference. Our coatings are used in all sorts of different environments — from commercial and industrial spaces to residential homes.They are designed to lower long-term floor care costs, enhance your floors’ appearance, and also often to improve floor traction. contact us today to get a free quote on new floor coatings!

ContactUS